-

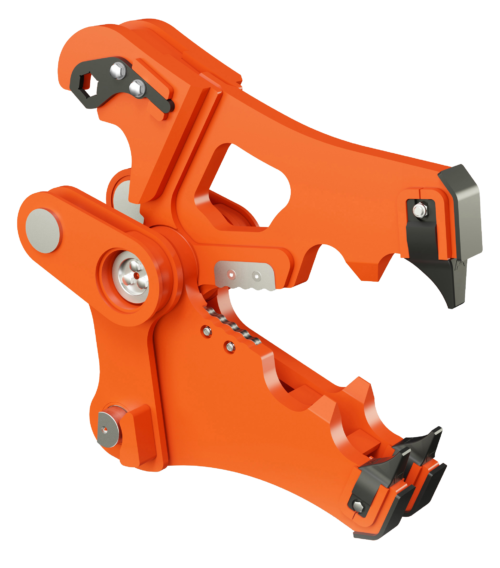

Specifically designed for primary demolition, the PD range is the best dedicated solution for standard and high reach demolition machines. Engineered with two cylinders, two pivot points, big jaws opening with high closing forces to the material is the right tool to be used for demolishing thickest reinforced concrete, such as bridges, viaducts, heavy foundations, and quaysides.

Specifically designed for primary demolition, the PD range is the best dedicated solution for standard and high reach demolition machines. Engineered with two cylinders, two pivot points, big jaws opening with high closing forces to the material is the right tool to be used for demolishing thickest reinforced concrete, such as bridges, viaducts, heavy foundations, and quaysides. -

Specifically designed for primary demolition performances, the HP range is the best suggested tool for excavator with high reach arm with operative elevation over 20 m. Engineered with one cylinder, two pivot points, big jaws opening with a constant closing forces to carry out specialised demolitions of artefacts and structures of high elevation.

Specifically designed for primary demolition performances, the HP range is the best suggested tool for excavator with high reach arm with operative elevation over 20 m. Engineered with one cylinder, two pivot points, big jaws opening with a constant closing forces to carry out specialised demolitions of artefacts and structures of high elevation. -

The VF Fixed Pulveriser Series is an excellent choice for recyclers who need to pre-crush and prepare concrete created during building demolition for fine crushing. Designed for secondary demolition. Concrete chunks produced during demolition can be fine-crushed at the job site. Concrete is separated from rebar and reduced for saving volume, dumping and transportation costs.

The VF Fixed Pulveriser Series is an excellent choice for recyclers who need to pre-crush and prepare concrete created during building demolition for fine crushing. Designed for secondary demolition. Concrete chunks produced during demolition can be fine-crushed at the job site. Concrete is separated from rebar and reduced for saving volume, dumping and transportation costs. -

The VF Fixed Pulveriser Series is an excellent choice for recyclers who need to pre-crush and prepare concrete created during building demolition for fine crushing. Designed for secondary demolition. Concrete chunks produced during demolition can be fine-crushed at the job site. Concrete is separated from rebar and reduced for saving volume, dumping and transportation costs.

The VF Fixed Pulveriser Series is an excellent choice for recyclers who need to pre-crush and prepare concrete created during building demolition for fine crushing. Designed for secondary demolition. Concrete chunks produced during demolition can be fine-crushed at the job site. Concrete is separated from rebar and reduced for saving volume, dumping and transportation costs. -

The CK Multiprocessor consists of a universal body to which different demolition jaws kits are hooked. Thanks to an innovative release semi-automatic system you do not have to remove structural pins manually and can change the kit in 5 minutes. Available with Primary, Pulveriser, Combi, Swiss, Shear and Tank jaws.

The CK Multiprocessor consists of a universal body to which different demolition jaws kits are hooked. Thanks to an innovative release semi-automatic system you do not have to remove structural pins manually and can change the kit in 5 minutes. Available with Primary, Pulveriser, Combi, Swiss, Shear and Tank jaws. -

The MT Multiprocessors offers a versatile range of solutions suited for both primary and secondary demolition applications. This Multiprocessor consists of a main body, to which it is possible to mount different types of jaws transforming it into a dedicated attachment for your specific application: Demolition of structures, reduction and fragmentation of material up to the cutting of ferrous materials and wood.

The MT Multiprocessors offers a versatile range of solutions suited for both primary and secondary demolition applications. This Multiprocessor consists of a main body, to which it is possible to mount different types of jaws transforming it into a dedicated attachment for your specific application: Demolition of structures, reduction and fragmentation of material up to the cutting of ferrous materials and wood. -

The SC is a multi-processor that can tackle all types of demolition, from Primary to Secondary and Selective (Strip out). It consists of a main body equipped with two cylinders to which different types of jaws can be fitted for the most diverse demolition activities, crushing, cutting, and recycling of concrete and steel structures and artefacts. The SC's versatility allows it to work on different types of materials, from the least resistant to the more tenacious, ensuring the maximum efficiency in terms of operation and working time. Its technology helps to reduce the environmental impact and increase the overall productivity of demolition operations. With the VTN SC, operators can work with greater safety, precision, and flexibility, reducing the use of auxiliary equipment.

The SC is a multi-processor that can tackle all types of demolition, from Primary to Secondary and Selective (Strip out). It consists of a main body equipped with two cylinders to which different types of jaws can be fitted for the most diverse demolition activities, crushing, cutting, and recycling of concrete and steel structures and artefacts. The SC's versatility allows it to work on different types of materials, from the least resistant to the more tenacious, ensuring the maximum efficiency in terms of operation and working time. Its technology helps to reduce the environmental impact and increase the overall productivity of demolition operations. With the VTN SC, operators can work with greater safety, precision, and flexibility, reducing the use of auxiliary equipment. -

The CK Multiprocessor consists of a universal body to which different demolition jaws kits are hooked. Thanks to an innovative release semi-automatic system you do not have to remove structural pins manually and can change the kit in 5 minutes. Available with Primary, Pulveriser, Combi, Swiss, Shear and Tank jaws.

The CK Multiprocessor consists of a universal body to which different demolition jaws kits are hooked. Thanks to an innovative release semi-automatic system you do not have to remove structural pins manually and can change the kit in 5 minutes. Available with Primary, Pulveriser, Combi, Swiss, Shear and Tank jaws. -

The FP Rotating Pulveriser Series is designed to last long and have a high level of breaking forces to thrust through materials quickly. They are used for demolishing and recycling on job sites where noise pollution and vibrations cannot be tolerated. Its characteristics allow to handle a job site with the primary & secondary demolition phases with a single piece of equipment.

The FP Rotating Pulveriser Series is designed to last long and have a high level of breaking forces to thrust through materials quickly. They are used for demolishing and recycling on job sites where noise pollution and vibrations cannot be tolerated. Its characteristics allow to handle a job site with the primary & secondary demolition phases with a single piece of equipment. -

The FP Rotating Pulveriser Series is designed to last long and have a high level of breaking forces to thrust through materials quickly. They are used for demolishing and recycling on job sites where noise pollution and vibrations cannot be tolerated. Its characteristics allow to handle a job site with the primary & secondary demolition phases with a single piece of equipment.

The FP Rotating Pulveriser Series is designed to last long and have a high level of breaking forces to thrust through materials quickly. They are used for demolishing and recycling on job sites where noise pollution and vibrations cannot be tolerated. Its characteristics allow to handle a job site with the primary & secondary demolition phases with a single piece of equipment.

CALL NOW ON 087 781 1632 TO GET A QUOTEAMAZING NEW PRODUCTS JUST ADDED

We regret to announce the untimely passing of Gary O’Shaughnessy, who was tragically involved in an accident. In light of this, we want to assure you that business operations will continue as usual. For any enquiries, please reach out to Robert O’Shaughnessy at 087 781 1632. Additionally, for matters related to accounts, please contact Declan Reidy at declanreidy@taxassist.ie or call +353 (0)86 791 6852.